The Cassava Compact is led by IITA with partnerships in 15 countries of Central, East, Southern and West Africa. Because cassava is suited to a wide range of climatic conditions, its toolkit approach varies across agro-ecological zones. Africa is the world’s leading cassava producer, but the crop is widely regarded as a food for the poor rather than a substrate for value-added food and industrial starch production. As a result, few cassava products from Africa are traded on world markets and this Compact seeks to rectify this shortcoming by intensifying cassava’s production and processing. Stalling cassava’s progress was its susceptibility to a number of serious virus diseases but after decades of research tolerant varieties and management systems are now in place. These new varieties are also selected on the basis of their higher dry matter and starch contents and some represent biofortified yellow (vitamin A) traits.

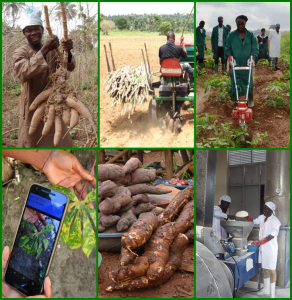

Cassava is propagated by stem cuttings and technologies are now available to rapidly multiply and commercially disseminate these improved varieties. This “seed” system includes laboratory propagation using Semi Autotrophic Hydroponics technology, distributing these plantlets to commercially- or community-operated fields producing stem cuttings, and then selling these cuttings to farmers employing other modern farming techniques. This dissemination is advanced through mechanized stem cutters and planters among larger-scale producers.

Soil fertility is managed through sequential addition of fertilizers based upon the stage of crop development and culminates in the addition of a specialized fertilizer blend rich in potassium (e.g. RFC-Root), a nutrient in high demand by the crop during tuber fill but not widely available through current agrodealer networks.

Cassava is resilient with regard to its water relations and can be grown across semi-arid to humid climates, but drought tolerant varieties are now available and are being disseminated where needed. Cassava is a longer duration crop with potential to accumulate weeds, pests and diseases during its growth. Competition with weeds greatly reduces cassava yields and established mechanized tools including rotary and paddle weeders are being promoted, as well as wider use of pre- and post-emergent herbicides.

Established IPM systems that reduce virus vectors are disseminated through extension providers in a way that compliments disease management through improved access to virus-free planting materials. Disease diagnosis is assisted through use of a mobile phone application. Because of cassava’s large stature and deep tubers, mechanized harvest “lifting” operations are difficult, but are under consideration as well. A simple “waxing” technology that improves shelf life of tubers is being promoted. Processing technologies focus upon the production of high quality flour and industrial grade starches, as well as use of peels as animal feed. Indeed, the potential for greatly increased production of cassava exists through application of this toolkit and increased processing capacities are needed to translate these surpluses into exports.